1.The machine tools are the mature products designed by referring to the advanced technologies globally. The machine tools adopt the structure of flat bed and slant saddle : integral body and foot , which are made by Resin sand casting . fully-protective all-in-one layout of 30° inclined sliding plate make the transverse feeding movement on the saddle guideway , the feed speed of the longitudinal and transverse direction can be as high as 30m/min . The structure of flat bed and slant saddle to reduce the installation of the gear box , tailstock and saddle , which improves the rigidity of the whole machine

2.Lathe bed is designed by two areas :chip collecting and watershed, which can well focuses coolant flow to the tank, to avoid the leakage

3.The numerical control system is FANUC 0i- Mate-TD plus servo drive and the servo spindle .the machine tools can accomplish the processing of linear, arc and metric system and English system threads and are suitable for the processing of the discs and axles that have complicated cutting shapes and require high precision.

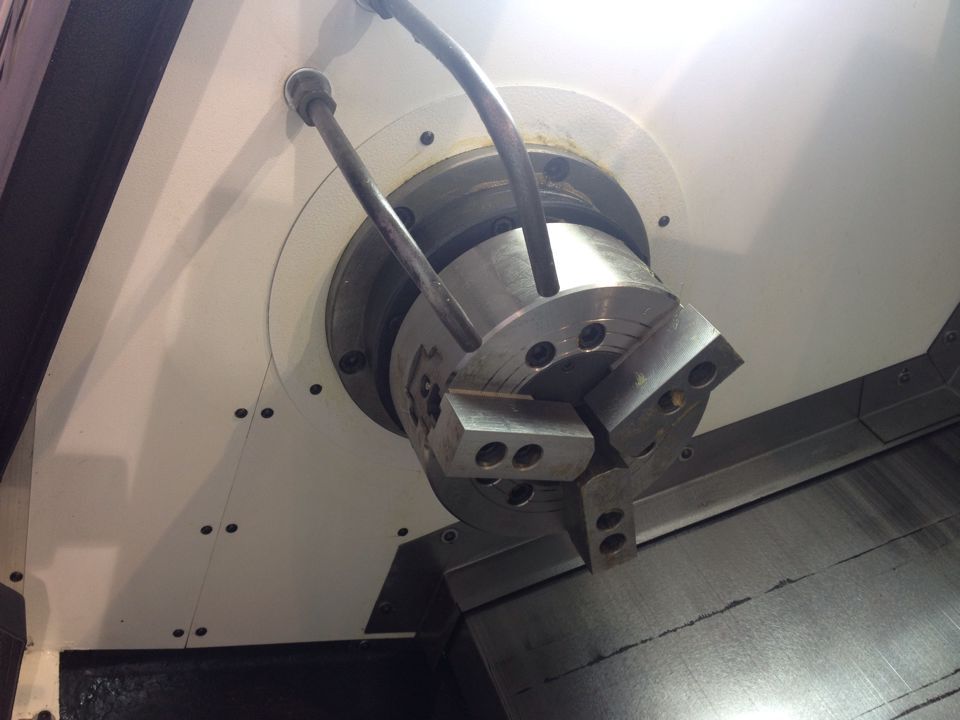

4.The spindle box and lathe bed have reliable positioning, and firm, with good rigidity, vibration resistance, thermal resistance and convenient maintenance and adjustment .Principal axle bearing set by Japan NSK and the principal axle with precise assembly and undergoing dynamic balance test are adopted, ensuring the high precision, low noise and strong rigidity of the principal axle and able to realize stepless speed regulation an constant speed cutting, quick start and stop.

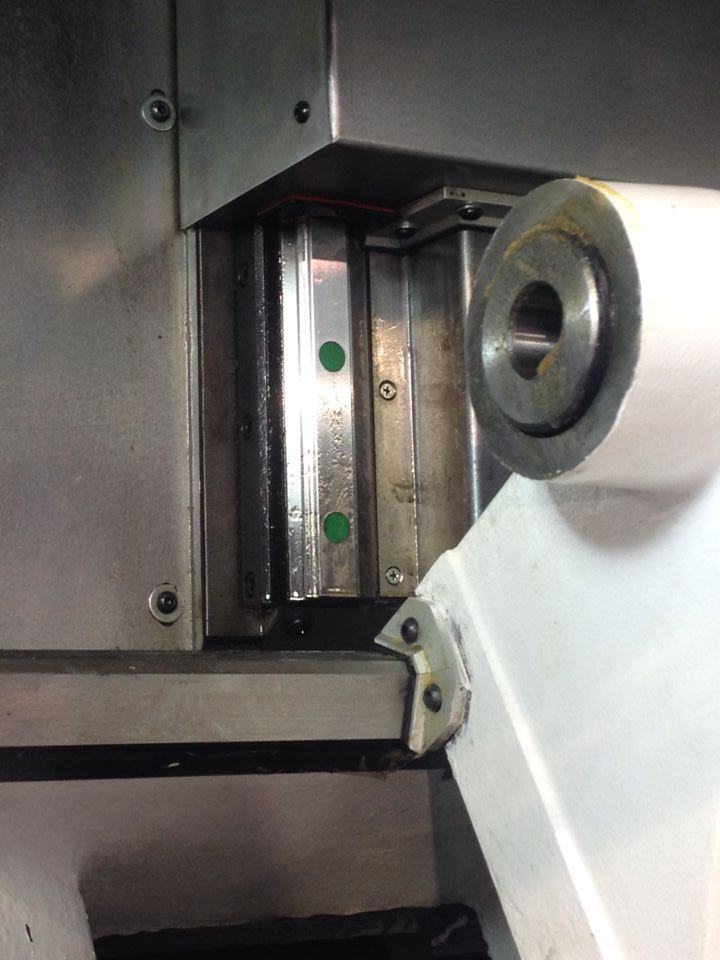

5.Both of the X and Z axis ballscrew are from Taiwan and bearing from JAPAN NSK./NTN, Ball screw and motor through coupling the directly connected, single-ended positioning pre-stretching type, lathe bed guide rail and sliding saddle guideway adopt high precision rolling guide, contact stress, rigidity, machining accuracy retaining ability is good.

6.Horizontal screw fixed end design on the front end, make machine not increase the cutting depth when ballscrew is heated and stretch , avoid to cause the workpiece scrapped. Screw pre-stretching structure was designed, and also to improve the lead screw bearing rigidity.

7.The tailstock with built-in hydraulic sleeve structure, compact and reliable. With Morse 4 center , pressure is adjustable.

8.The tailstock with built-in hydraulic sleeve structure, compact and reliable. Configuration Morse 4 top, top pressure is adjustable.

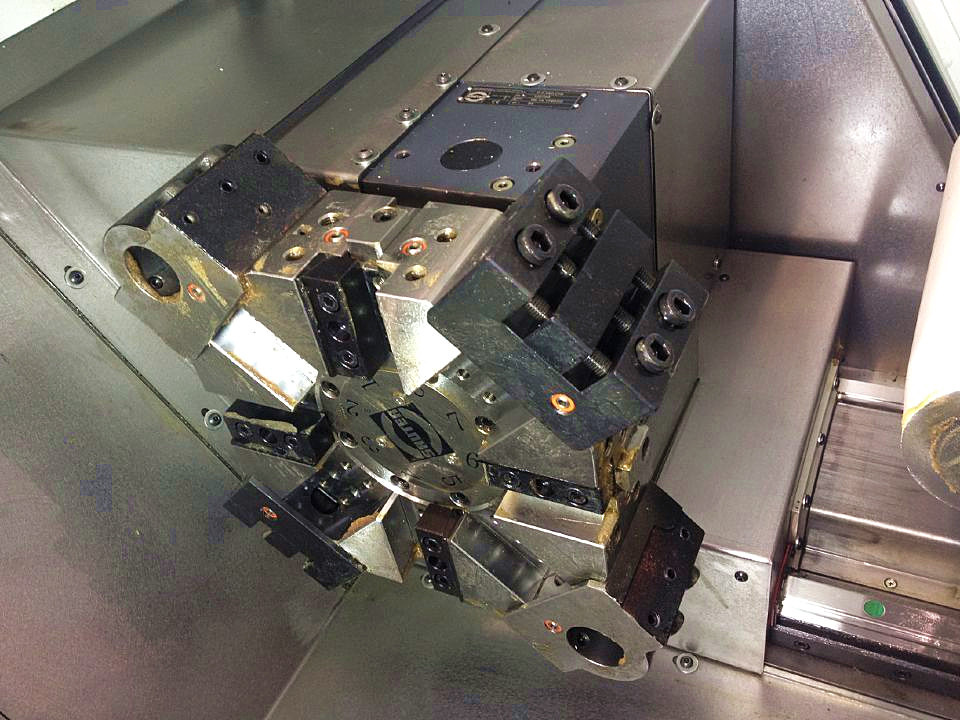

9.The machine tools adopt the hydraulic 8-station rotary turret by Taiwan , which can rotate clockwise and anti-clockwise, have tool change of the shortest path quickly, excellent positioning rigidity and high repeated positioning precision.

10.The hydraulic chuck (φ210mm) with 8″ standard through hole and through hole reversing oil tank (including cut-off valve) by Taiwan AUTO STRONG are adopted; pedal switch can be used to control the tightening and release of work pieces.